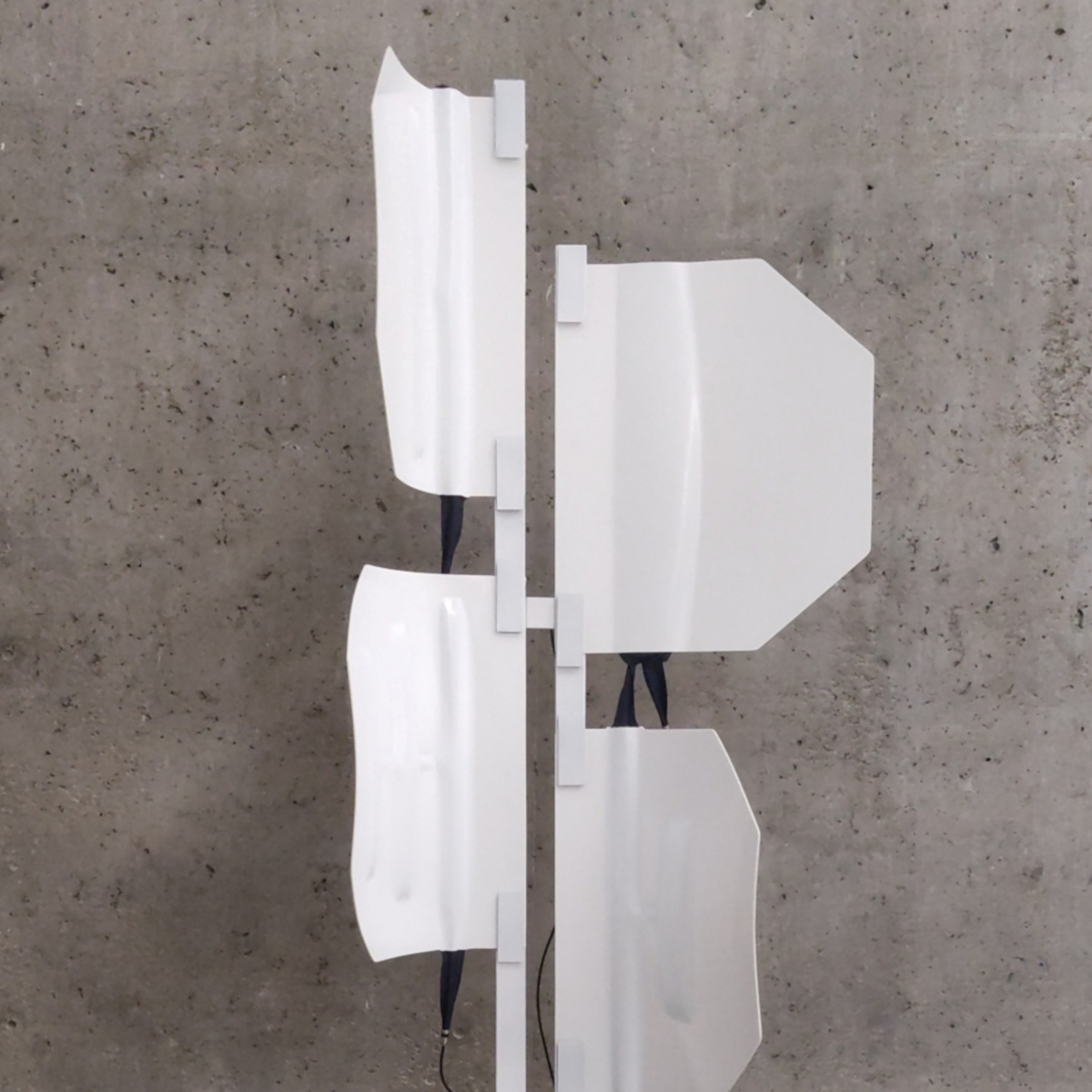

The research demonstrator FlectoCurve of the A03 BioElast project shows the potential of transferring plant movement principles into technical components. Analogous to turgor pressure/veins in a plant/leaf, pneumatic actuators were integrated into two-dimensional fiber-reinforced composite components. The fiber-reinforced composite components consist of elastomer, glass fiber-reinforced plastic and a TPU coating. The actuator is pressed asymmetrically into the layer structure so that a one-sided curvature occurs when air pressure is applied.

It turns out that the stiffness of the component can be adjusted not only by means of the laminate setup, but also by means of the cushion geometry. A curved cushion, for example, also curves the surface of the element and thus creates structural stiffness in the component. The research demonstrator thus meets the requirements for façade shading components in terms of wind stability.

Project Team

ITKE Institute of Building Structures and Structural Design

University of Stuttgart

Prof. Dr.-Ing. Jan Knippers

ITFT Institute for Textile and Fiber Technologies

University of Stuttgart

Prof. Dr.-Ing. Götz T. Gresser

PBG Plant Biomechanics Group Freiburg

University of Freiburg

Dr. rer. nat. Olga Speck

Design Development

Mona Mühlich, Axel Körner

Scientific Development

Larissa Born, Mona Mühlich, Axel Körner

Funding

The research of the project was funded by the Ministry of Science, Research and the Arts Baden-Württemberg within the project Bio-inspired Elastic Material Systems and Composite Components for Sustainable Construction in the 21st Century (BioElast A03). In addition, the work was partially supported by the German Research Foundation (DFG) under the German Excellence Strategy EXC 2120/1-390831618.

Contact

Larissa Born

Dr.-Ing.Deputy Director